BEST SELLERS

NEW IN

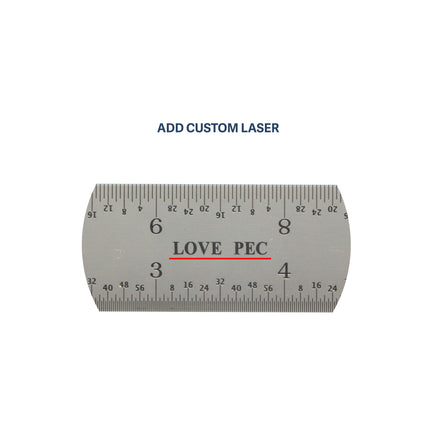

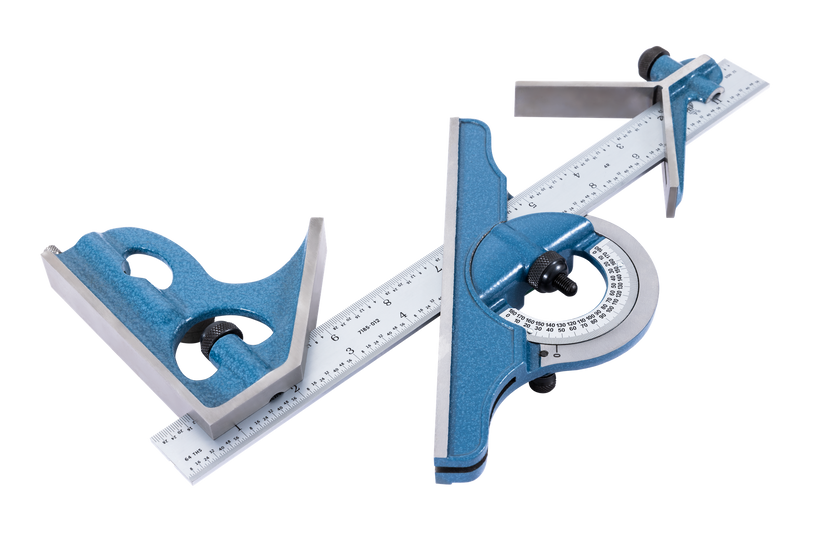

Bring your tool designs to life with state-of-the-art prototyping

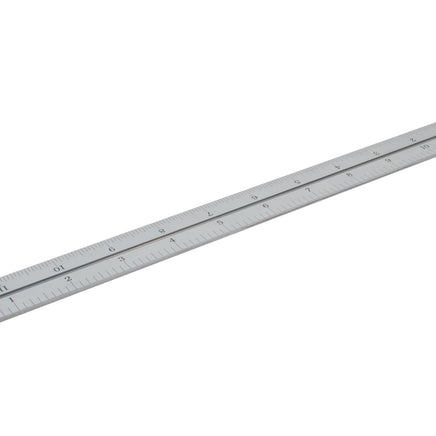

Featuring high-contrast and micro-fine blade graduations that define a new standard of quality in craftsmanship.

INDUSTRIES WE SERVE

Add text to share customers about your store, products, brand.

WHAT OUR CLIENTS ARE SAYING

FEATURED CONTENTS

Article published at:

September 29, 2025

Getting accurate measurements starts with the right tool. In this guide, we’ll help you choose the best PEC ruler based on structure, material, finish — whether you’re a machinist, woodworker, or quality inspector, you’ll find precise and reliable options to fit your work.

Since 1960, PEC Tools has been a trusted name in precision craftsmanship. From surface-plate work to curved layouts, our rulers are engineered for lasting accuracy, clarity, and durability — helping you build a toolkit you can depend on.

If you need help finding the right ruler graduation for your work, see our blog here!

1) Rigid vs. Flexible: Different Structures, Different Advantages

When choosing the right PEC ruler, structure matters. The rigidity or flexibility of your rule affects both accuracy and usability. Here’s how to select the ideal ruler for your workflow — whether you’re working on a flat surface, curved layout, or tight workspace.

Rigid Rulers

Profile: Thicker, wider, and highly resistant to deflection.

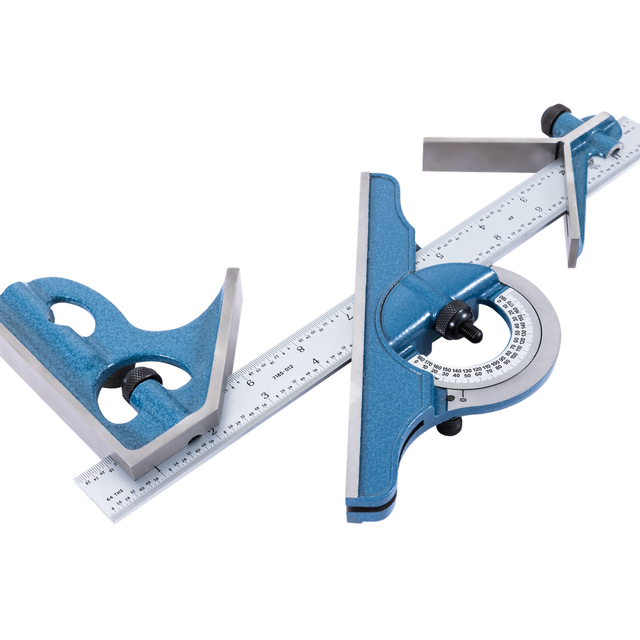

Best For: Flat-stock layouts, scribing lines, bench work, and reference readings with squares, height gauges, and combination sets.

Why Choose: Keeps your readings on the same plane, minimizes bending errors, and stabilizes your baseline for maximum accuracy.

Ideal Users & Applications:

Machinists, toolmakers, and QC/QA inspectors performing surface-plate work, fixture setup, and gauge alignment

Woodworkers laying out tenons, dados, and cabinet faces on flat stock

Model makers and precision assemblers needing a stable straightedge for consistent bench-based measurements

Flexible Rulers

Profile: Lightweight, slim, and designed to conform to curved or irregular surfaces.

Best For: Measuring curves, cylinders, inside arcs, and tight spaces where a straight rule won’t sit flush.Why Choose: Maintains full contact on non-flat work so your contact points and readings stay accurate.

Ideal Users & Applications:

Pipefitters, sheet-metal, and HVAC technicians measuring around tubes, ducts, and rolled stock

Automotive and maintenance professionals checking hose and pipe runs, curved panels, and interior contours

Industrial designers and model makers tracing compound curves on prototypes or 3D prints

Woodworkers and boatbuilders laying out arcs, edge-banding paths, and laminations on curved work

2) Materials & Finishes: Balance Readability, Durability, and Environment

Selecting the right PEC ruler finish ensures optimal readability, durability, and performance in your specific work environment. Below is a comparison of PEC’s available finishes and their best use cases.

Satin Chrome Plating on Carbon Steel

Best For: Environments requiring high durability, easy readability, and resistance to reflection — ideal for professionals seeking a matte, low-glare measuring tool that performs reliably in demanding shop conditions.

Why Choose: This precision measuring tool features satin-chrome plating over carbon steel for excellent wear resistance and crisp, long-lasting graduations. The low-glare finish surface ensures clear readings under LED task lights, while the fingerprint-resistant coating keeps the ruler clean and mark-free.

Ideal Users & Scenarios:

Production machinists and inspectors working under strong LED lighting who need a low-glare machinist ruler with high-contrast readings

General shop benches requiring rugged PEC rulers with legible markings for daily layout and measurement tasks

Training and instructional labs using durable PEC Tools rulers designed for frequent use and consistent accuracy

Stainless Steel (Uncoated)

Best For: Work environments that demand corrosion protection, easy maintenance, and reliable readability in humid or oily conditions — ideal for professionals needing a durable, corrosion-proof measuring tool suited for both field and shop use.

Why Choose: Built from solid, uncoated stainless steel, this PEC precision ruler delivers long-lasting performance without the need for additional plating. The smooth surface wipes clean easily after exposure to oil or coolant, ensuring consistent accuracy in industrial and maintenance settings where hygiene and resilience matter most.

Ideal Users & Scenarios:

Machining cells and maintenance crews exposed to oil, cutting fluids, or high humidity

Field service and outdoor technicians prioritizing rust resistance and fast cleanup

Food, medical, and prototyping labs requiring uncoated stainless steel for sanitary use

Black Nickel Chrome on Stainless Steel

Best For: Reducing eye strain in workspaces with harsh lighting, low ambient light, or camera-based inspection setups — ideal for professionals who need a low-glare precision ruler with high-contrast graduations for accurate readings in any lighting condition.

Why Choose: Featuring a dark nickel-chrome coating over stainless steel, this PEC low-glare measuring tool offers exceptional readability by minimizing reflections and eye fatigue. The enhanced contrast makes it especially effective for documentation, inspection reports, and design work requiring crisp, clear visibility under both bright glare and dim light.

Ideal Users & Scenarios:

QC and QA stations capturing measurement photos or inspection documentation

Reflective workbenches where glare control improves reading speed and accuracy

Designers, drafters, and inspectors requiring high-legibility rulers for precision work

Technical environments where lighting conditions vary and visual clarity is critical

Titanium Nitride (TiN) Gold Tone Finish

Best For: Professionals who need a durable, wear-resistant measuring tool with a premium appearance — ideal for shared workshops, training environments, and customer-facing setups where quick tool identification and visual appeal matter.

Why Choose: Carbon steel coated with titanium nitride (TiN) in a distinctive gold tone delivers exceptional hardness and a scratch-resistant surface. The bright finish makes it easy to spot in busy tool sets, while finely etched graduations provide superior accuracy for high-precision layout, scribing, and inspection work.

Ideal Users & Scenarios:

QC and QA stations capturing measurement photos or inspection documentation that require glare-free, high-contrast visibility

Reflective workbenches and brightly lit environments where glare control improves reading speed, comfort, and accuracy

Designers, drafters, and inspectors who need high-legibility rulers for detailed precision work under varying light conditions

Customer-facing benches, demo kits, and training labs where a professional, premium appearance enhances presentation quality

Technical and engineering environments where lighting conditions vary and visual clarity is essential for consistency

Read article

Article published at:

September 09, 2025

Find the Right PEC Tools Starter Kit for Woodworking, Machining, Automotive, and More | Precision-Made Tool Bundles That Save Time and Money

Read article

Article published at:

July 30, 2025

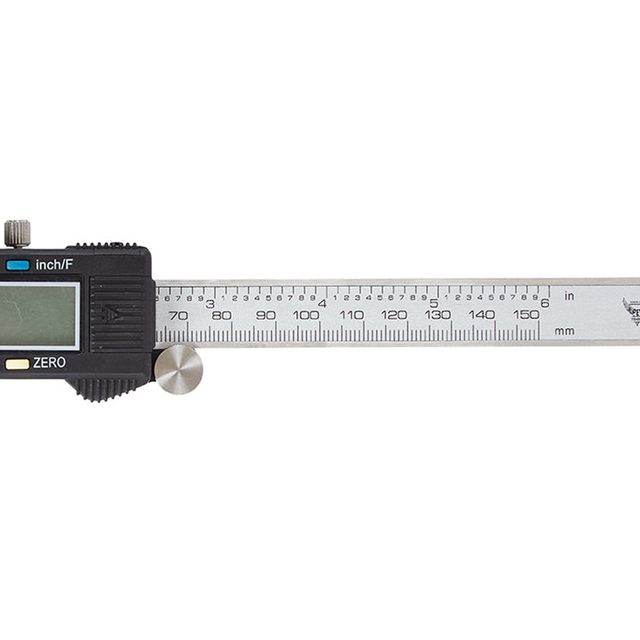

Digital and Dial Calipers – Precision Measuring Tools for Professionals

Read article

Article published at:

June 26, 2025