BEST SELLERS

NEW IN

Bring your tool designs to life with state-of-the-art prototyping

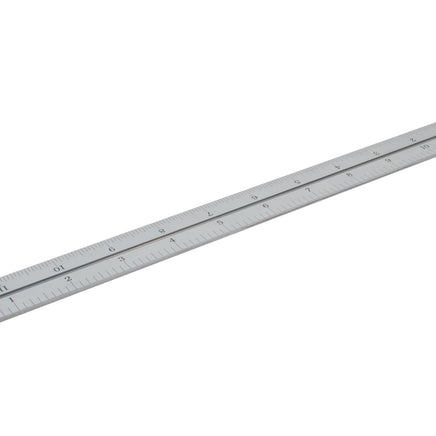

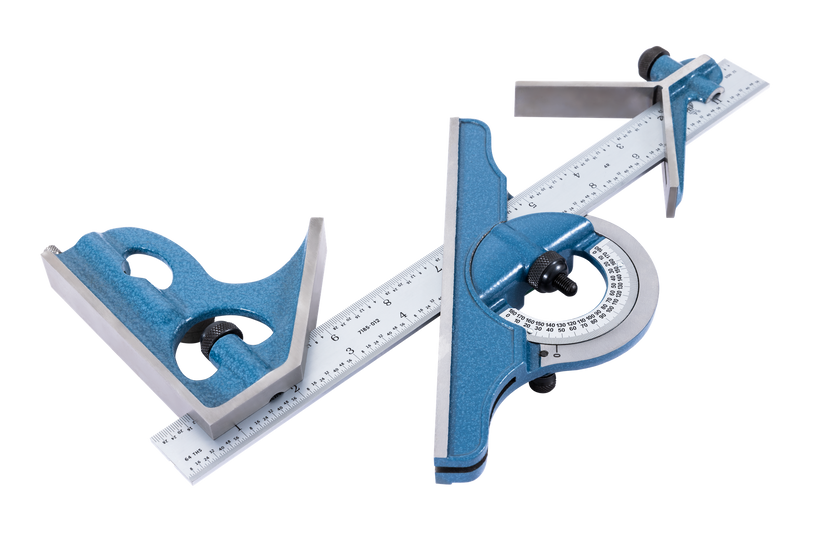

Featuring high-contrast and micro-fine blade graduations that define a new standard of quality in craftsmanship.

INDUSTRIES WE SERVE

Add text to share customers about your store, products, brand.

WHAT OUR CLIENTS ARE SAYING

FEATURED CONTENTS

Article published at:

June 26, 2025

Engineering the Future—One Measurement at a Time

We’re proud to announce that PEC Tools is sponsoring the University of California, Irvine’s Formula SAE (FSAE) team in their 2025 competition build. The FSAE event is a collegiate-level design challenge where students across the continent come together to engineer, build, and race their own formula-style vehicles. It’s an immersive hands-on project that pushes the boundaries of design, testing, and teamwork—mirroring the demands of real-world engineering.

At UCI, the student team is building a race car for the “DV” category, focusing on electric vehicle development. Every part they create, from the battery assembly to the suspension system, is designed and built from scratch—requiring precision that meets or exceeds professional engineering standards.

Precision Isn’t Optional—It’s Essential

That’s where PEC Tools comes in. From digital and dial calipers to micrometers, our precision tools have been part of every step in UCI’s build process. “The two main PEC tools that I use a lot are the digital calipers and the micrometer,” one student shared. “I use them every day in the machine shop to verify our components when machining.”

Another student emphasized the 6-inch caliper as a daily go-to for quick, reliable measurements. The team also highlighted their use of dial calipers during torsional rigidity testing—a crucial process for ensuring the chassis doesn’t twist under load. “On an uneven road, you don’t want the car to just buckle under its own forces,” one engineer explained. “This is a great way of determining torsional stiffness.”

In a build where tolerances stack and fractions of a millimeter can compromise performance, high-quality measurement isn’t just a convenience—it’s mission critical. “Precision is huge,” a student said. “Making sure that everything is accurate as we’re building really is important the whole time.”

Learning for the Track—and Beyond

Beyond the technical aspect, the experience has inspired students to envision careers in automotive and electric vehicle design. “This program has shown me there’s a lot more possibility out there than I thought,” one team member noted. “I do see myself working in the EV industry after school.”

We’re honored to support this kind of growth. As one student put it, “The quality we’re seeing [from PEC] is exceptional. We trust the final dimensional stability of those parts, and we’d definitely recommend them to other teams—and personally as well.”

Watching this next generation of engineers take charge—with care, curiosity, and technical excellence—reminds us why we do what we do. Whether it’s aerospace, machining, or a student-led EV prototype, PEC is proud to be part of every bold build.

Join Us in Shaping the Future of Precision

Whether you're a student engineer pushing the limits of design or a seasoned professional in aerospace, manufacturing, or automotive, PEC Tools is here to support your next breakthrough with tools you can trust.

Interested in partnering with us or learning more about our precision solutions?Reach out anytime at sales@pectools.com! We'd love to hear from you.

Precision starts with the right tools. Let’s build something extraordinary, together.

Read article

Article published at:

March 18, 2025