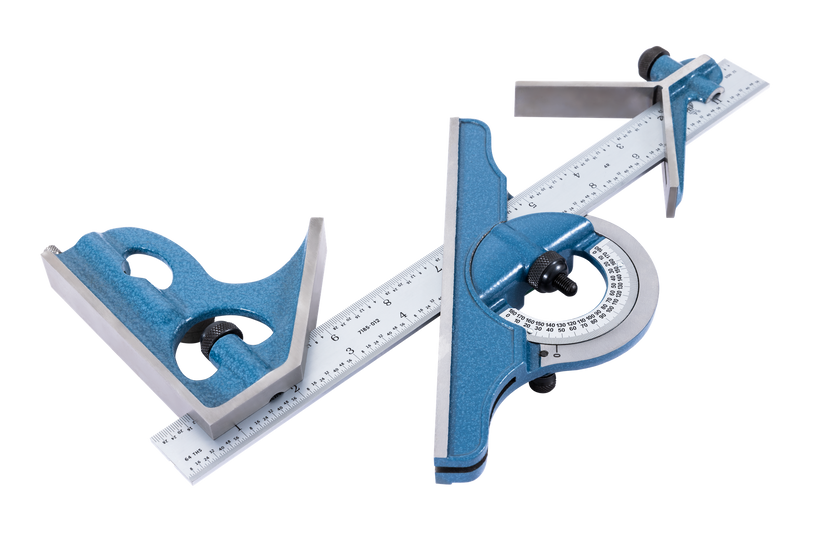

BEST SELLERS

Bring your tool designs to life with state-of-the-art prototyping

Featuring high-contrast and micro-fine blade graduations that define a new standard of quality in craftsmanship.

INDUSTRIES WE SERVE

Add text to share customers about your store, products, brand.

WHAT OUR CLIENTS ARE SAYING

FEATURED CONTENTS

Article published at:

March 18, 2025

Precision is the backbone of any machine shop—whether you’re a seasoned professional or a dedicated hobbyist, the right machinist rule can make all the difference in your metrology results. In this guide, we’ll delve into the distinct features of 3R, 4R, 5R, 16R, E/M, D/M, and Metric machinist rules, explaining how each style helps you achieve accurate, reliable measurements. By the end, you’ll know exactly which graduation style best fits your precision measurement needs and where to find your best fit machinist tools at PEC Tools.

1. 3R Graduations

Typical Increments: 1/32” & 1/64” on one side, 0.1” & 0.02” on the other.

Primary Use: Ideal for tasks requiring both fractional and decimal readings without switching tools.

Who It’s For: Machinists and metalworkers who frequently convert between decimal and fractional inches.

Key Advantages:

Combines fractional and decimal readings in one tool.

Suitable for fast conversions during layout and measurement.

2. 4R Graduations

Typical Increments: 1/8” & 1/16” on one side, 1/32” & 1/64” on the other.

Primary Use: A go-to choice for many everyday tasks in the workshop.

Who It’s For: Woodworkers, general tradespeople, and DIY users who typically work in fractional measurements.

Key Advantages:

Versatile for most standard layout and marking tasks.

Offers a complete range of common fractional increments.

3. 5R Graduations

Typical Increments: 1/32” & 1/64” on one side, 0.1” & 0.01” on the other.

Primary Use: Balances precision decimal readings with fine fractional measurements.

Who It’s For: Inspection technicians and precision machinists requiring tight tolerance control.

Key Advantages:

High-resolution measurement options.

Excellent for dimensional verification and quality assurance.

4. 16R Graduations

Typical Increments: 1/32” & 1/64” on one side, 0.02” & 0.01” on the other.

Primary Use: Ultra-fine decimal-inch readings for high-precision applications.

Who It’s For: Mold makers, toolmakers, and metrologists working to extremely fine tolerances.

Key Advantages:

Provides ultra-fine decimal resolution.

Perfect for high-precision shop and lab environments.

5. E/M – English/Metric Scales

Typical Increments: 1/32” & 1/64” on one side, 1 mm & 0.5 mm on the other.

Primary Use: Enables easy conversion between imperial fractions and metric units.

Who It’s For: Engineers, technicians, and contractors working across imperial and metric systems.

Key Advantages:

Ideal for international or dual-standard projects.

Allows quick transitions between systems without switching tools.

6. D/M – Decimal Inch/Metric Scales

Typical Increments: 0.1” & 0.02” on one side, 1 mm & 0.5 mm on the other.

Primary Use: Optimized for CNC programming and environments using decimal and metric input.

Who It’s For: CNC operators and engineers who work in both decimal inch and metric systems.

Key Advantages:

Simplifies the measuring process in high-precision machining.

Pairs well with digital readout systems and CAD tools.

7. Metric Graduations

Typical Increments: 1 mm & 0.5 mm on both sides.

Primary Use: Standard for scientific, academic, and metric-only industrial applications.

Who It’s For: International users and professionals in metric-dominant regions.

Key Advantages:

Simple, standardized metric layout.

Ideal for schools, labs, and public infrastructure projects.

How to Choose the Right Increment

1. Identify the Measurement Format in Your Project

If your plans are strictly fractional, a 4R rule is ideal.

If you occasionally work in decimals, 3R gives you both fractional and decimal formats.

If your work relies on decimal-inch dimensions, 5R or 16R are better suited — with 16R offering ultra-fine resolution.

For global or metric-based projects, choose an E/M, D/M or Metric scale depending on your format preference.

2. Consider Project Complexity

4R provides the most common fractional increments for everyday machinist layouts.

3R is great for machinists who frequently work in both fractional and decimal inch formats and need quick conversions between the two.

5R balances precision decimals and fine fractions, ideal for inspection and part fitting.

16R is excellent for high-precision tasks requiring fine decimal readings.

E/M and D/M are flexible options when switching between metric and imperial.

3. Think About Long-Term Convenience

If your workload changes often or involves global standards, E/M or D/M scales offer the best versatility.

If your tasks are specialized and consistent, you can choose a dedicated fractional or metric/decimal scale.

Metric rules are best for international work environments, science labs, academic settings, and engineering fields where metric is the standard.

4. Quality and Durability Matter

Always choose rulers made from hardened and tempered steel with clear, durable graduations.

PEC Tools rulers are designed to last through years of daily shop use.

Why Choose PEC Tools?

At PEC Tools, we understand that accurate measurement is the foundation of excellent workmanship. We offer:

Superior Materials: Hardened, wear-resistant steel.

Precision Markings: Laser-etched or engraved graduations that won’t wear off.

Extensive Graduation Options: From 3R to 16R, plus E/M, D/M, and full Metric-only scales to support any measuring standard.

Trusted Craftsmanship: Decades of experience trusted by machinists, engineers, and quality inspectors alike.

Read article